Electric Vehicle Supply Equipment (EVSE) and EV Charging Solutions

Electrical Vehicle Supply Equipment applications

Successful deployment of EVSE goes hand in hand with simple recharging and energy management processes. This implementation requires the incorporation of new technologies and consistent development of robust standards that cater to various charging technologies suited for different applications.

Furthermore, there are significant indicators emanating from various regions that seek to accelerate the deployment of charging infrastructure, including regulatory initiatives such as the Alternative Fuel Infrastructure Regulation and the Fit for 55 law package in Europe, as well as programs like the NEVI in the United States.

To accomplish this, precise and innovative electrical measurement technologies are needed to perform functions such as current sensing, energy metering, and electrical safety.

Additionally, the infrastructure requires resilient current sensing technologies to ensure smooth operations.

Understanding EV Charging technologies for BEVs and E-Trucks

Charging Options for Passenger Battery Electric Vehicles (BEVs)

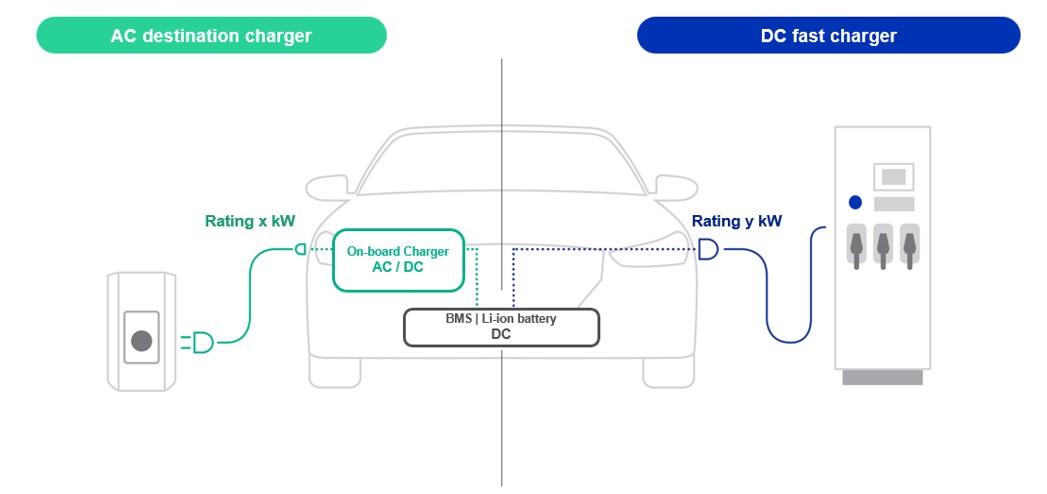

For passenger Battery Electric Vehicles (BEV), charging is performed using either using AC wallbox – using the automotiveon-board charger (OBC) of the vehicle – or an off-board DC charger with a maximum charging power usually in the range of 100-250kW.

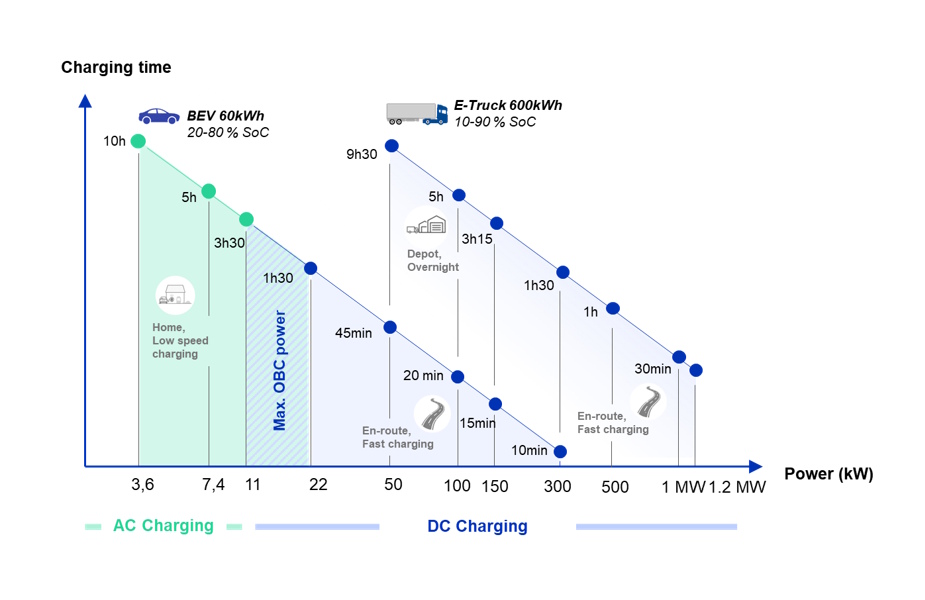

Selecting AC of DC charging point and power level for BEV will depend on the time available to charge and the desired charging range.

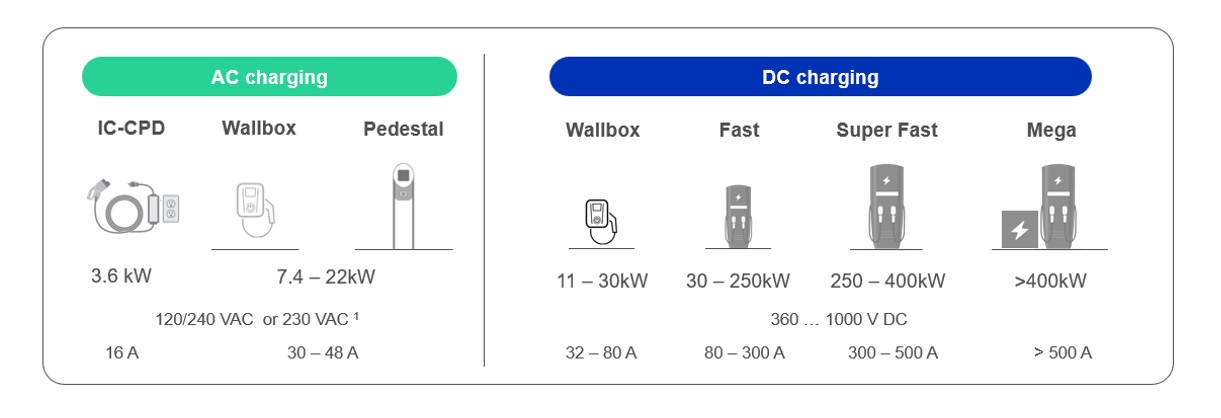

For passenger BEV application, AC charging points constitute most of the volume and are usually deployed in home and building while DC charging points are deployed for destination charging and en-route charging where time is an important constraint.

How to charge a BEV - AC and DC chargers

The Impact of High-Power Chargers Development on E-Trucks

With heavy-duty vehicles, particularly e-trucks, battery sizes are usually within the range of 300-600 kWh.

Using AC charging with an on-board AC/DC converter at conventional power levels of 11…22 kW would result in excessively long charging times, even for overnight depot charging.

Hence, it is anticipated that e-truck charging will predominantly rely on DC charging, ranging from 50 kW up to Megawatt charging.

Charging times and technologies for BEVs and E-trucks

The ongoing development of high-power chargers for passenger car BEVs directly benefits to this, with Direct Current chargers being widely available up to 400 kW and in development up to the megawatt scale.

Notably, regulations mandate a mandatory 45-minute break every 4.5 hours of driving. Under these conditions, and assuming standard consumption and speed, charging power in the range of 700-1000 kW is required for en-route charging of long-haul e-trucks.

Comparing AC and DC Charging: Speed, Cost, and Availability

Access to convenient and widely accessible electrical vehicle supply equipment is a cornerstone of the transition towards electrification in the transportation sector.

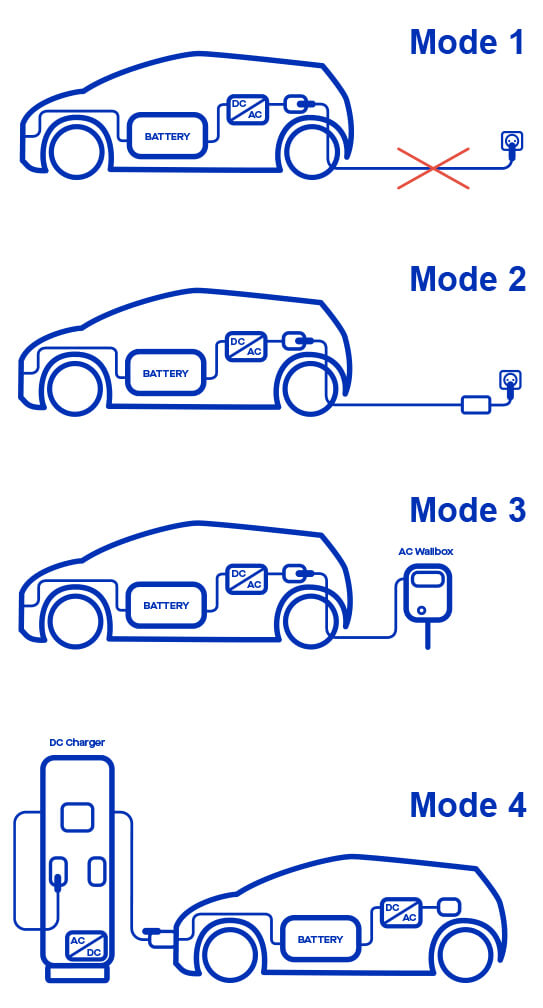

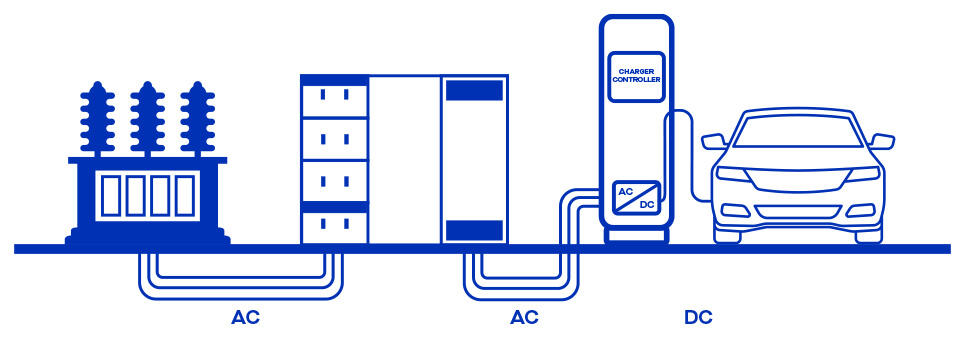

There are two options to charge a Battery Electric Vehicle (BEV): utilizing the on-board charger (OBC) of the BEV or connecting an external AC/DC converter directly to the BEV's battery.

The choice between AC and DC charging depends on factors such as available charging time and the cost of the charging technologies.

AC charging is often referred to as low-speed charging, employing cost-effective hardware. In contrast, DC charging allows for rapid charging because the power of the automotive OBC becomes no longer a limit, but necessitates more expensive equipment (the off-board DC fast charger).

DC fast charging is essential for on-the-go charging, meeting the demand for approximately 30-minute charging times for 20-80% State-of-Charge (SOC). It plays a crucial role in removing range anxiety and promoting widespread availability of charging points in public spaces.

On the other hand, AC charging constitutes the majority of chargers in residential areas, providing a substantial volume of charging options.

EV charging solutions: AC and DC chargers

Charging Modes

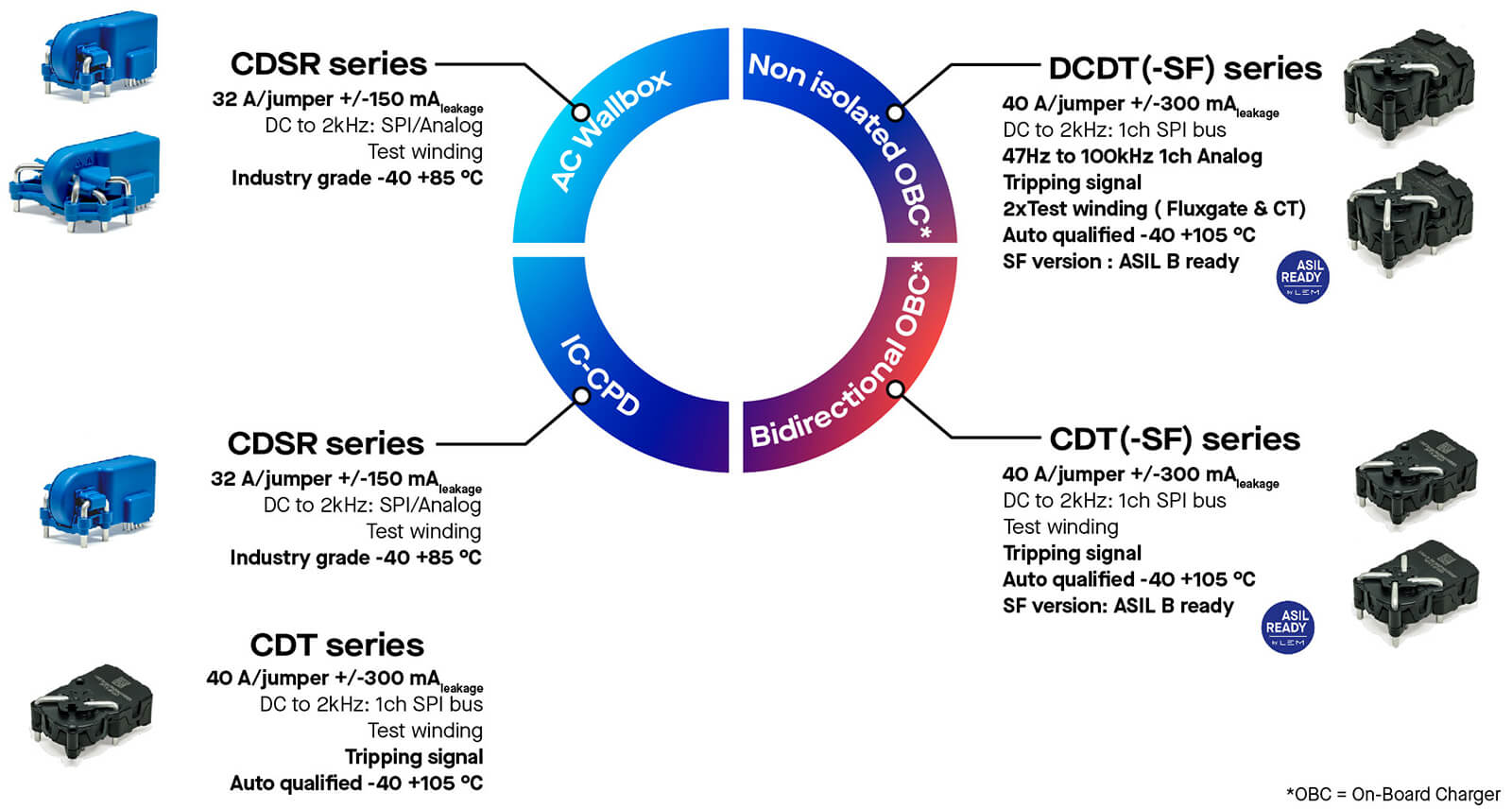

Leakage current sensor

LEM Residual Current Detection (RCD) portfolio for 6 mA DC / 30 mA AC compliant with IEC 62752 and UL 2231 standards.

- Design with compact solutions with single & 3 phase version

- Digital output (SPI bus) and Analog

- Tripping Signal, with settable threshold option via SPI (Flexibility to decide the adequate standard late in design)

- Tests windings for customer

- Complies with standards Industrial (CDSR) and Automotive (CDT) grade versions

Documentation:

CDSR at a glance

Current sensors for Power Module

Current control loop for Power modules

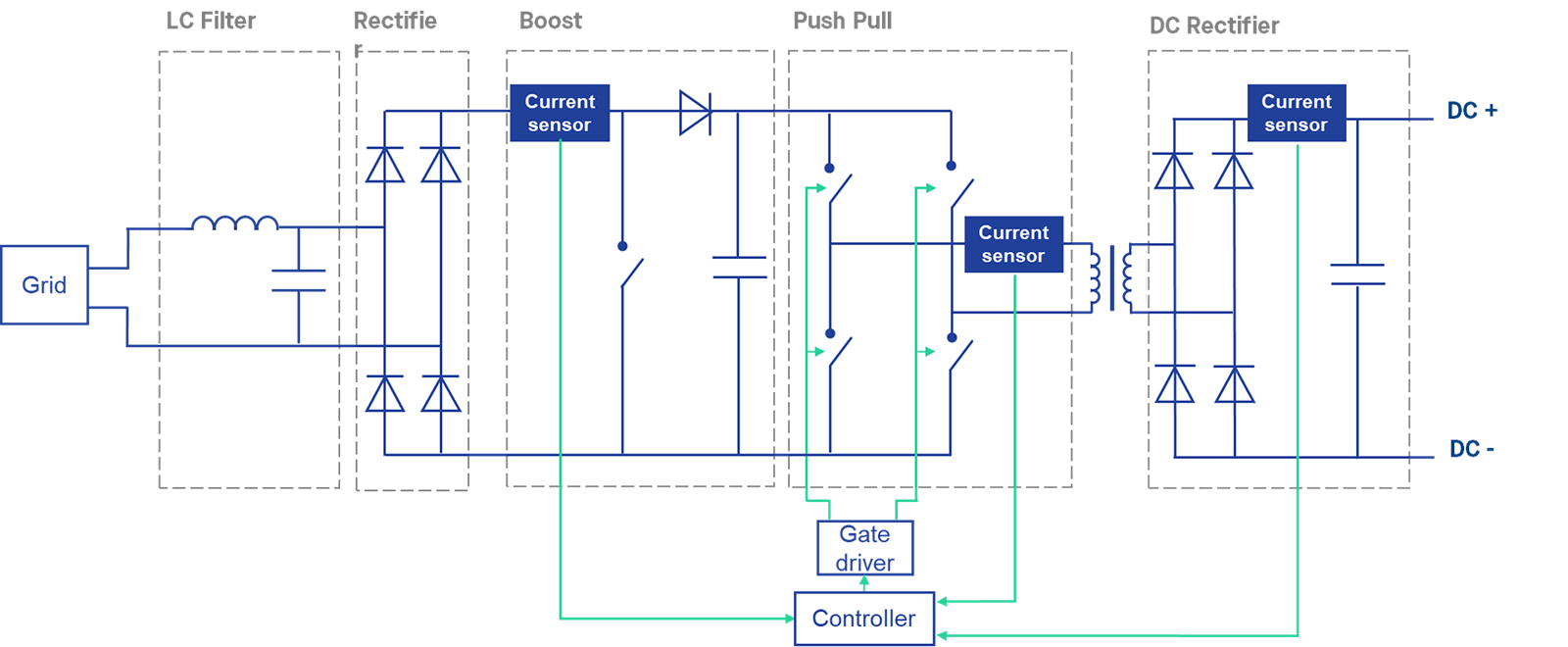

LEM provides a wide range of current sensors for power module converters, transforming the Alternative Current to a Direct Current. Power converters are placed in stacks to increase the power of DC fast charging stations, up to 400kW. In average eight converters are present. In each power module, current sensors are necessary to ensure the control loop function which regulate the stability and the power of inverters.

HMSR

Click to sensor page description

PRODUCT DOCUMENTATION

As the demand for electric vehicles grows, so does the need for high-performance charging infrastructure. Discover how LEM’s advanced current sensing technologies help enhance the efficiency, safety, and reliability of EV Supply Equipment.

Our EV Charging Solutions Brochure provides in-depth insights into how our innovative solutions can transform your EV charging systems for a cleaner, more sustainable future.

DC Meter smart billing

プロジェクトにお困りですか?

アプリケーション向けプロジェクトを保有しLEM社とのご相談要望はございますか?

以下の問合わせボタンをクリックください。弊社の専門家がお客様のニーズに最適なソリューションを見つけるお手伝いをいたします。