Industrial automation

Electrical signals are the power source for all manufacturing processes, machines and systems. In addition, they enable the fast and reliable supervision of equipment and facilities. LEM integrated transducers take this a step further by providing your complete process with increased control and reactivity. They combine advanced sensing technologies and signal conditioning of electronic circuits (True RMS, industry standard outputs e.g. 0-5/10 V or 4-20 mA...).

Main applications for Automation

Increased process automation efficiency

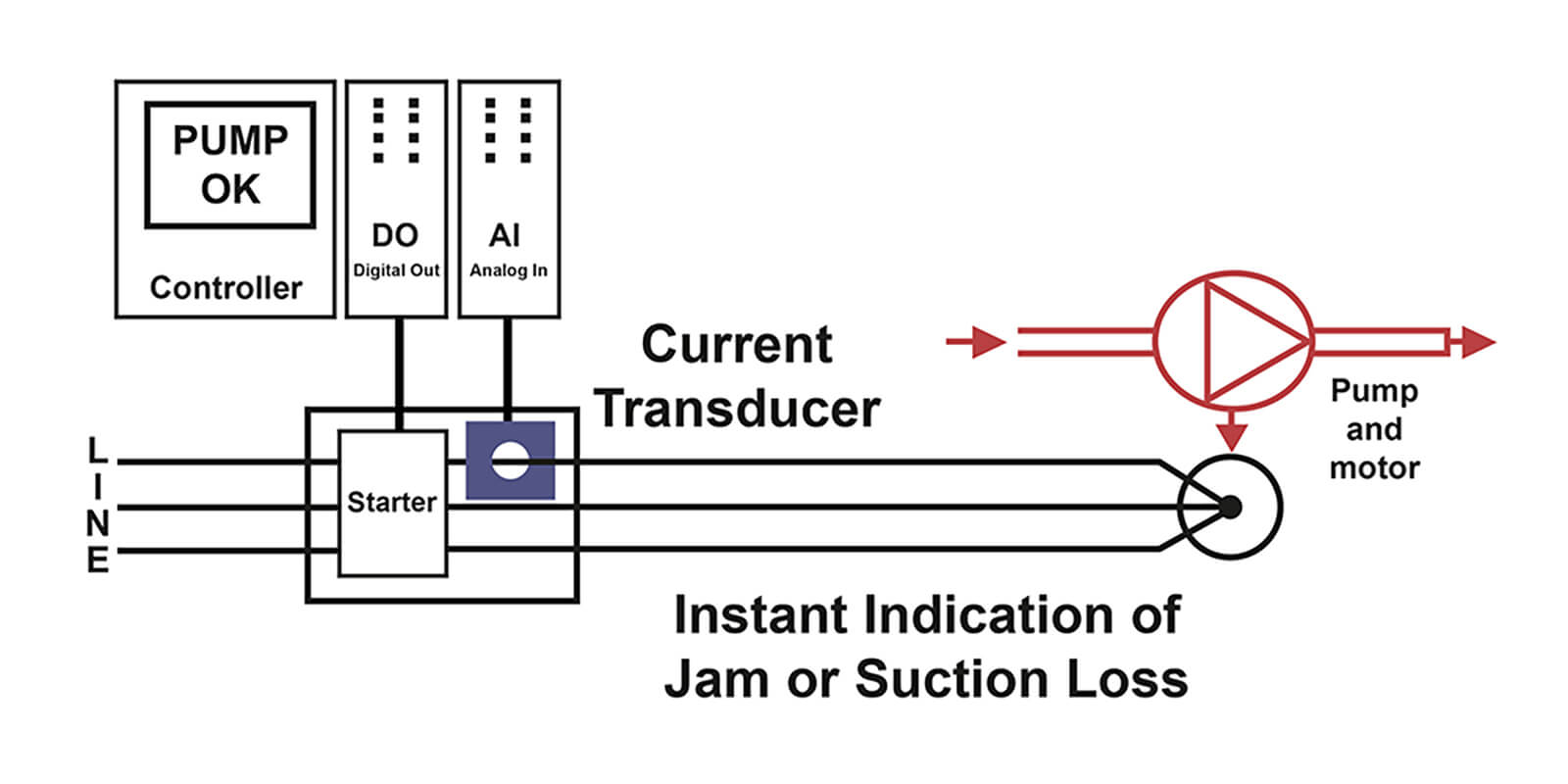

Traditional process control still implies monitoring and regulation of parameters such as temperature, pressure, torque, position, etc. But measuring these directly can be both inefficient and inaccurate. Measuring the input current of a load provides much more information than just the current value and has a number of advantages like speed, ease of use, reliability, and savings. An increasing number of process automation and condition monitoring applications are following this trend.

Installing electrical transducers in control panels or on electric motor drives allows:

- monitoring of the status of various kinds of electro-mechanical installations

- regulation of miscellaneous parameters

- failure warning

- back-up system launch

Typical applications for Automation

- Machine and panel builders

- System integrators / engineering

- Safety operations and personnel protection (

- Process control: supervision and automation (, smelting furnace, electrolysis process, Electro-mechanical installations monitoring…)

- Maintenance operations: condition monitoring (

- Facilities & infrastructures management (, cathodic protection current, drives used to convey materials…)

- Energy production and consumption ( Site energy sub-metering)

Products for automation

Application example

Certificates and standards

Compliance with the highest industry standards

LEM products and processes comply with reference standards in the industry:

- CE marking of LEM transducers in recognition of their electromagnetic compatibility

- IEC standards for automation applications:

- IEC 61869-2,-6,-8, -10, -14, -15, for performances

- IEC 61010-1, -2-030, -2-032, -031 for safety

- IEC 61800-1 & -2 for climatic and mechanical constraints

- IEC 61326-1 for EMC

- RoHS compliant

- ISO TS 16949 certification of all production and development centers (Switzerland and China)

Quality products and services: our priority

Based on our deep knowledge of applications and current measurement technologies, LEM develops both catalog and customized products which can be perfectly tailored to meet your needs in terms of performance, space requirement and cost.

Need help with a project?

You have a project in line with that application and want to discuss it with LEM?

Click on the contact button below and our experts will help you find the best solutions for your needs.