ON-BOARD ELECTRIC TRACTION SYSTEMS

Modes of public transport such as high-speed trains, city transit systems (metro, trams, trolleybuses…) and freight trains provide the ideal solution to meet the increased demand for more mobility whilst helping to fight pollution and traffic congestion. Power electronics are essential for driving and controlling energy in these systems.

More than five decades of railway experience have contributed to establishing LEM as the market leader for on-board electrical measurement solutions. We engineer, manufacture and deliver our sensors, transducers and energy meters anywhere in the world to ensure efficient, safe and reliable operation of the railways.

RAIL TRACTION: ON-BOARD ELECTRICAL MEASUREMENT

For both electric or diesel-electric trains, traction is provided by electric motors driven by inverters that rely on LEM traction sensors to measure, optimize and adjust the power sent to the motors, improving performance and reliability of the whole system.

LEM transducers provide control and protection signals to power converters and inverters that regulate energy both to the electric motors (for propulsion) and to the auxiliaries (for air-conditioning, heating, lighting, electrical doors, ventilators, etc).

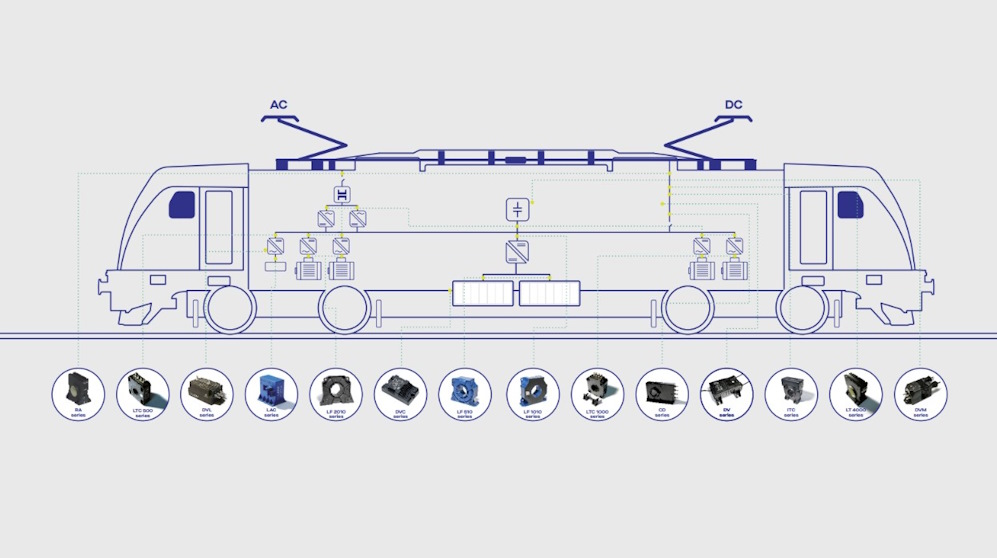

WHERE TO MEASURE ELECTRICAL PARAMETERS ON-BOARD?

On AC-trains, the energy flows from the pantograph into a transformer, which transforms the voltage to 2.8kV or lower. After, a rectifier transforms the voltage from AC to DC. Voltage sensors and current sensors are used to measure the current and the voltage on the secondary side of the transformer and on the DC-side.

Inverters are used to transform the energy into the right voltage and current to drive the motors, usually one motor per axis or every second axis. Special differential transducers are implemented at the secondary side of the transformer to detect any leakage current flowing in the train.

Besides the main drive, additional inverters are used for heating, air-conditioning and ventilation. They are called auxiliary inverters and normally placed under the roof or under the car body of a traction vehicle.

Sensors are used to measure the motor currents and to optimize their efficiency.

ON-BOARD CURRENT SENSORS

Accurate and insulated current measurement plays a crucial role in supporting the efficiency of power electronics onboard trains.

Additionally, LEM provides specialized solutions for measuring various currents within the locomotive, including input current for triggering the main circuit breaker, differential current for monitoring earth leakages, interference currents for controlling network harmonics, and high-precision DC currents for energy meter input.

For traction inverter applications in railway settings, Open Loop and Closed Loop technologies are widely employed. Additionally, more specific measurements, such as differential current measurement and energy metering, require Fluxgate sensors.

FRS, FL Series

- High Current Measurement: The FRS sensors can measure currents up to 9000 A, while the FL sensors can handle up to 42 kA, making them suitable for the high demands of traction systems.

- Open Loop Coreless Integral (OLCI) Technology: This technology ensures reliable and accurate current measurements with galvanic separation between primary and secondary circuits.

- Large Aperture Sizes: The FRS sensors feature a 104 mm aperture, while the FL sensors are available with 200 mm or 300 mm apertures, accommodating various installation needs in traction systems.

- High Accuracy and Signal Integrity: The sensors offer excellent accuracy and high signal integrity, with lower drift over temperature and lower noise compared to open loop alternatives.

Product Family | Nominal current | Output ratio | Vcc | error @25°C | Technology | Op. Temperature |

|---|---|---|---|---|---|---|

| LAC | 200 … 300A | 1:2000 to 1:5000 | +/- 15V or +/- 24V | 1.0% | Closed Loop | -40 … +85°C |

| LTC | 200 … 1000A | 1:1000 to 1:5000 | +/- 15V … +/- 24V | 0.5% | Closed Loop | -40 … +85°C |

| LF | 100 … 2000A | 1:1000 to 1:5000 | +/- 15V … +/- 24V | 0.2% or 0.7% | Closed Loop | -40 … +85°C |

| LT 4000 | 3 … 5kA | 1:4000 to 1:5000 | +/- 24V or +/- 60V | 0.5% | Closed Loop | -40 … +70°C |

| HAR | 500 … 1000A | +/- 5V | +/- 15V | 1.0% | -40 … +70°C | |

| DHR | 100 … 600A | 0 ... 5V | +20 … 50V | 1.0% | Open Loop | -25 … +70°C |

| HTC | 0.1 … 4kA | +/- 10V | +/- 15V | 1.0% | Open Loop | -40 … +85°C |

| ITC | 500 … 4kA | 1:2500 | +/- 24V | 0.05% | Fluxgate | -40 … +85°C |

| RA | 0.5kA … 2kA | M*di/dt | none | 3.0% | -40 … +85°C | |

| CD | 0.1A … 2kA | 20mA | +/- 48V or +/- 24V | 3.0% | Fluxgate | -40 … +70°C |

| FRS, FL | 9kA ... 42kA | 4mA - 20mA | 12V ... 24V | 0.5% | OLCI | -40 … +85°C |

ON-BOARD VOLTAGE SENSORS

Numerous railway applications demand accurate voltage measurement and stringent insulation characteristics. Compliant with EN 50163, our traction portfolio addresses the requirements not only for 1.5 and 3kV DC-networks in countries like France, Italy, Netherlands, etc., but also for metro and light rail tracks operating at the 600/750V level.

LEM provides a diverse array of voltage sensor technologies that ensure galvanic insulation between primary and secondary circuits. Notably, the Digital Voltage sensors deliver exceptional performance across the entire temperature range.

Product Family | Nominal current | Output ratio | Vcc | error @25°C | Test voltage |

|---|---|---|---|---|---|

| DVC | Up to 1000V | 10V | +/- 15V or +/- 24V | 1.0% | 4.26kV |

| DVL | 150 ... 2000V | 10V | +/- 15V or +/- 24V | 0.5% | 8.5kV |

| DVM | 1 ... 4.2 kV | 10V | +/- 15V or +/- 24V | 0.5% | 12kV |

| DV | 2 ... 6.4kV | 10V | +/- 15V or +/- 24V | 0.5% | 18.5kV |

| LV | 250 ... 2500V | 20mA | +/- 15V or +/- 24V | 0.8% To 1.0% | 4.1kV to 6.0kV |

| CV | 200 ... 2000V | 10V | +/- 15V | 0.2% | 6.0kV |

TRACTION ON-BOARD ENERGY METERING

The privatization of the rail networks raised new requirements and the need for reliable energy meters, compliant with regional networks.

Energy meters in traction applications measure the energy consumed and regenerated by trains, providing accurate data for billing and energy management. This helps optimize energy usage and ensures compliance with regulatory standards.

The liberalization and/or privatization of major rail networks has opened up opportunities for traction units to cross national boundaries, utilizing both existing and planned rail networks. This has led to the development of multisystem traction units capable of operating on different supply networks in various countries without the need for equipment exchange at regional or network supply borders. Presently, it is technically feasible to transport people or goods across Europe, from Norway to Sicily, for instance, without any physical exchange of locomotives.

Changes in the Energy Markets, driven by deregulation and increased competition for large user contracts, present potential benefits for those negotiating their electrical traction supply requirements.

However, successful negotiation requires a deep understanding of the load profile of bulk supply points in one of the most challenging electrical environments — the traction supply. LEM's energy meters provide the necessary data for precise calculation of both supplied and regenerated energy for billing purposes directly on the train, independent of the energy supplier.

For over a decade, EM4TII+ has been a central component of several Energy Metering Systems (EMS) in Europe. It includes mandatory functions such as ECF (Energy Calculation Function) and DHS (Data Handling System).

Furthermore, it can be ordered as a subsystem or integrated into LEM’s EMS solution called TEMA4G, which also features the PEMG2 communication device for transferring energy data to the ground.

EM4TII+ and TEMA4G are compatible with the most relevant current and voltage measurement devices (AC and DC), especially with LEM’s DC current and voltage sensors (DV and ITC series).

ON-BOARD METERING SOLUTIONS

LEM’s solutions for on-board energy metering provide highly accurate measurements, eliminating any uncertainties regarding the accuracy of the energy bill, from the energy supplier to the rolling stock operator.

All LEM equipment has been qualified to EN 50463:2017, making them suitable for use in all European countries where legally relevant energy measurement is required. Moreover, they are compatible for use in Asia and the Americas.

Meter | Nominal voltage | Output | GPS Interface | Vcc | Class accuracy |

|---|---|---|---|---|---|

| EM4TII+ | 25kV/50Hz 15kV/16,7Hz 750V 1.5/3kV | RS 232 RS 485 | RS232 (NMEA 0183 format) | +24 … 48V +72 … 110V | 0.5R |

| TEMA4G | 25kV/50Hz 16kV/16,7Hz 750V 1.5/3kV | 2G/4G Ethernet | GPS antenna, SMA connector | +24 … 48V +72 … 110V | 0.5R |

| PEMG2 | N/A | 2G/4G Ethernet | GPS antenna, SMA connector | Powered by EMaTII+ oder 12Vdc | N/A |

Certificates and standards

Compliance with the highest industry standards

LEM products and processes comply with reference standards in the industry:

- CE marking of LEM transducers in recognition of their electromagnetic compatibility

- EN standards for traction-based applications:

- EN 50155 for the electrical performances, environmental and safety constraints

- EN 50121-3-2 for EMC

- RoHS compliant

- ISO TS 16949 certification of all production and development centers (Switzerland and China)

- IRIS certification :

- Geneva Head Office since September 2007 (LEM Switzerland SA)

- Beijing production sites since 2008 (LEM Electronics China Co. Ltd)

- Sofia production site since 2016 (LEM Bulgaria EOOD)

Quality products and services: our priority

Based on our deep knowledge of applications and current measurement technologies, LEM develops both catalog and customized products which can be perfectly tailored to meet your needs in terms of performance, space requirement and cost.

PRODUCT DOCUMENTATION

Explore LEM's cutting-edge technologies designed for railway and traction applications. Our proficiency in railways extends beyond traction, encompassing inventive solutions for trackside applications as well.

Delve into the specifics and access our brochure for a comprehensive and insightful exploration:

Need help with a project?

You have a project in line with that application and want to discuss it with LEM?

Click on the contact button below and our experts will help you find the best solutions for your needs.