Electric Vehicle Supply Equipment (EVSE) and EV Charging Solutions

One of the biggest challenge of the 21st century will be to decarbonized the traditional transportation accountable for over 25% of global CO2 emissions. Decarbonization must be done without sacrificing the interconnectedness we've come to expect from modernity. With a fleet of 157 mil of EVs expected in 2030, the charging infrastructure needs to proceed in parallel, and sometimes anticipate that of the EV stock. LEM actively contributes to the deployment of electric vehicle charging stations, by supplying very high technology sensors and meters making the charging stations more reliable, safer, more affordable, and smarter.

Electric vehicle supply equipment (EVSE)

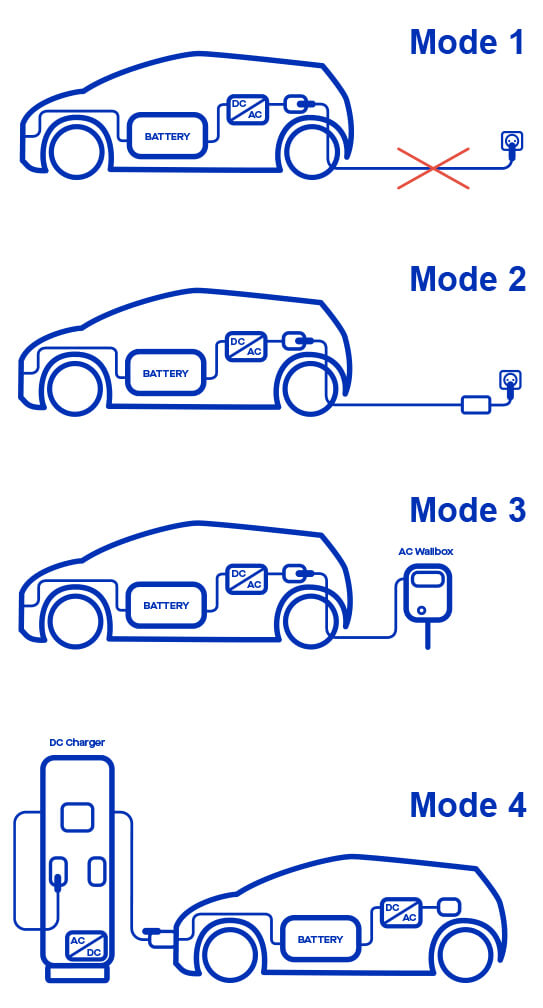

Two main families to charge a Electric Vehicle (EV) are dominant on the market, AC chargers, for Alternative Current charger and DC charger for Direct Current charger

AC chargers also known as Mode 2 (level 1) and Mode 3 (level 2) or are the most dominant charging family present on the market. This charging mode is able to charge an EV directly via a standard homehold socket, easily accessible from a garage, public or private. The technology of AC charger is also more affordable to due a less complexe electrical architecture and more compact due to the absence of power conversion stages, so more transportable. Nevertheless, his main drawback is its power limitation. AC chargers are able to deliver a power between 3.7 kilowatts and 44 kilowatts, but this charging power capability is also limited by the power of the conversion stage present inside the EV (OBC, On-Board Charger). Indeed EV batteries must be charged with a DC current, so an AC/DC inverter is placed inside the car to achieve this energy conversion. Thus, the charging time of an EV can vary between 12 and 2 hours.

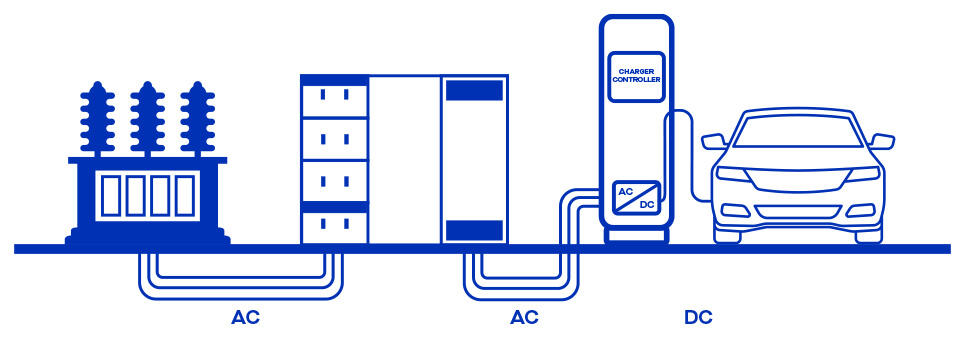

DC chargers, also known as level 3 or direct-current fast charging (DCFC). This charging system converts the AC from the grid to DC before it enters the car and charges the battery without the need for an inverter. Usually called direct-current fast charging or level 3, it operates at powers from 25 kilowatts to more than 350 kilowatts. Thus the EV battery is able to receive a direct power up to 350kW, reducing significantly the charging at 15 minutes for the fastest.

Charging Modes

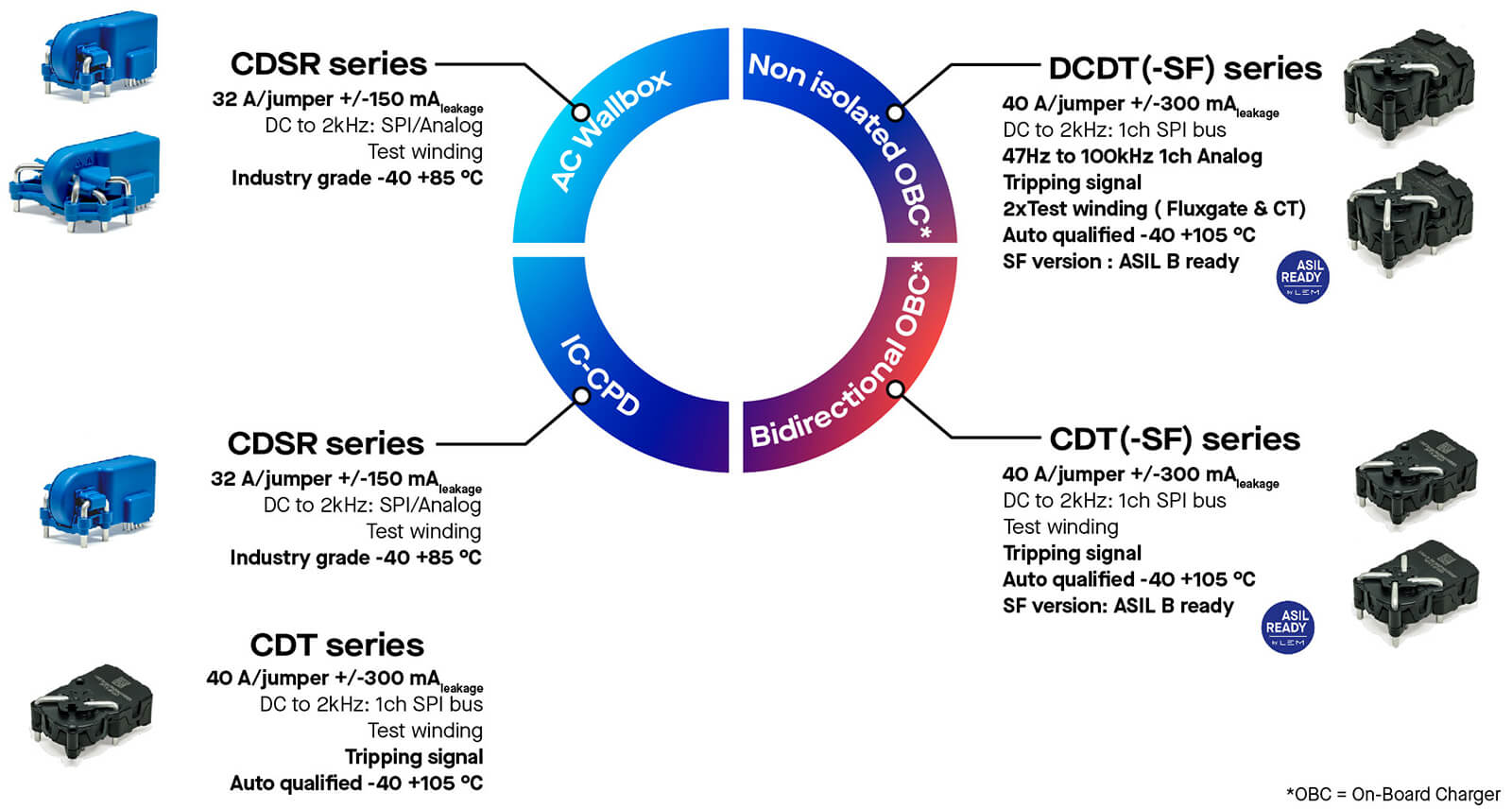

Leakage current sensor

LEM Residual Current Detection (RCD) portfolio for 6 mA DC / 30 mA AC compliant with IEC 62752 and UL 2231 standards.

- Design with compact solutions with single & 3 phase version

- Digital output (SPI bus) and Analog

- Tripping Signal, with settable threshold option via SPI (Flexibility to decide the adequate standard late in design)

- Tests windings for customer

- Complies with standards Industrial (CDSR) and Automotive (CDT) grade versions

Documentation:

CDSR at a glance

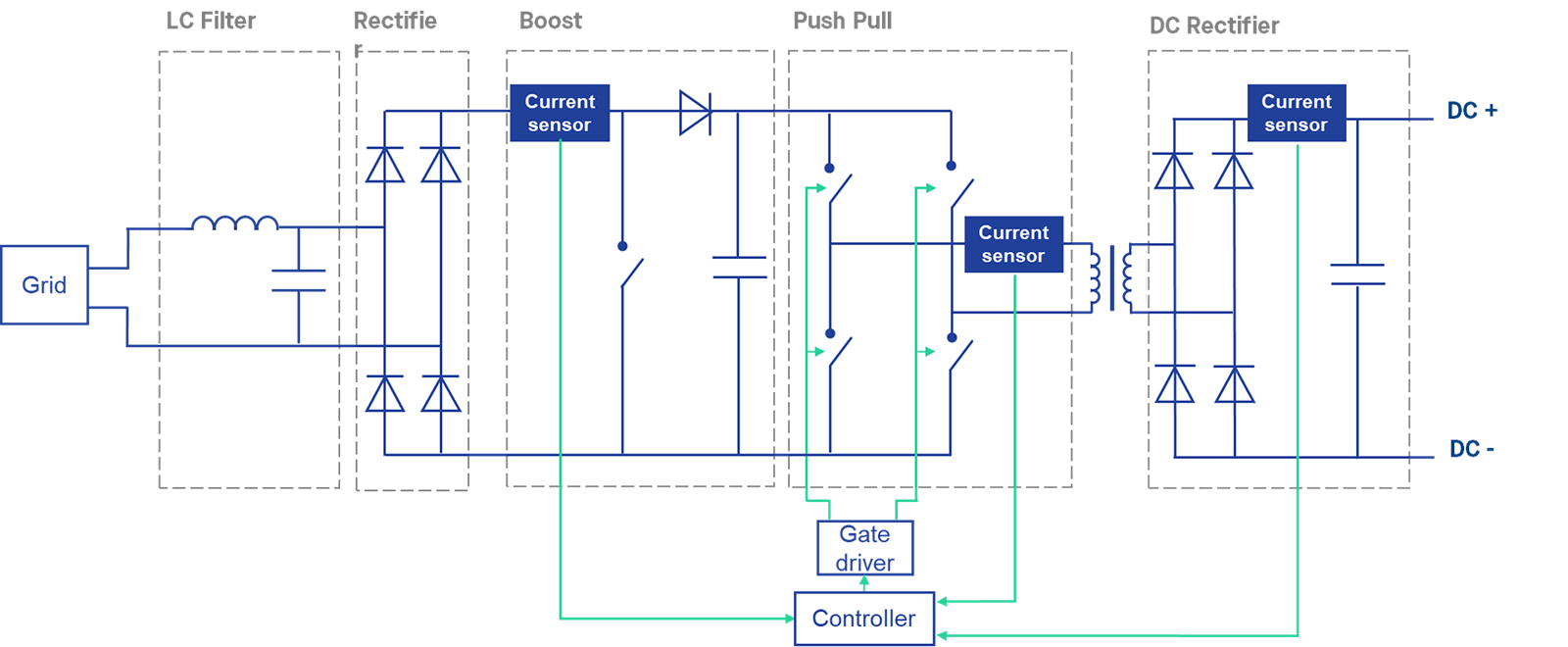

Current sensors for Power Module

Current control loop for Power modules

LEM provides a wide range of current sensors for power module converters, transforming the Alternative Current to a Direct Current. Power converters are placed in stacks to increase the power of DC fast charging stations, up to 400kW. In average eight converters are present. In each power module, current sensors are necessary to ensure the control loop function which regulate the stability and the power of inverters.

HMSR

Click to sensor page description

DC Meter for EV chargers

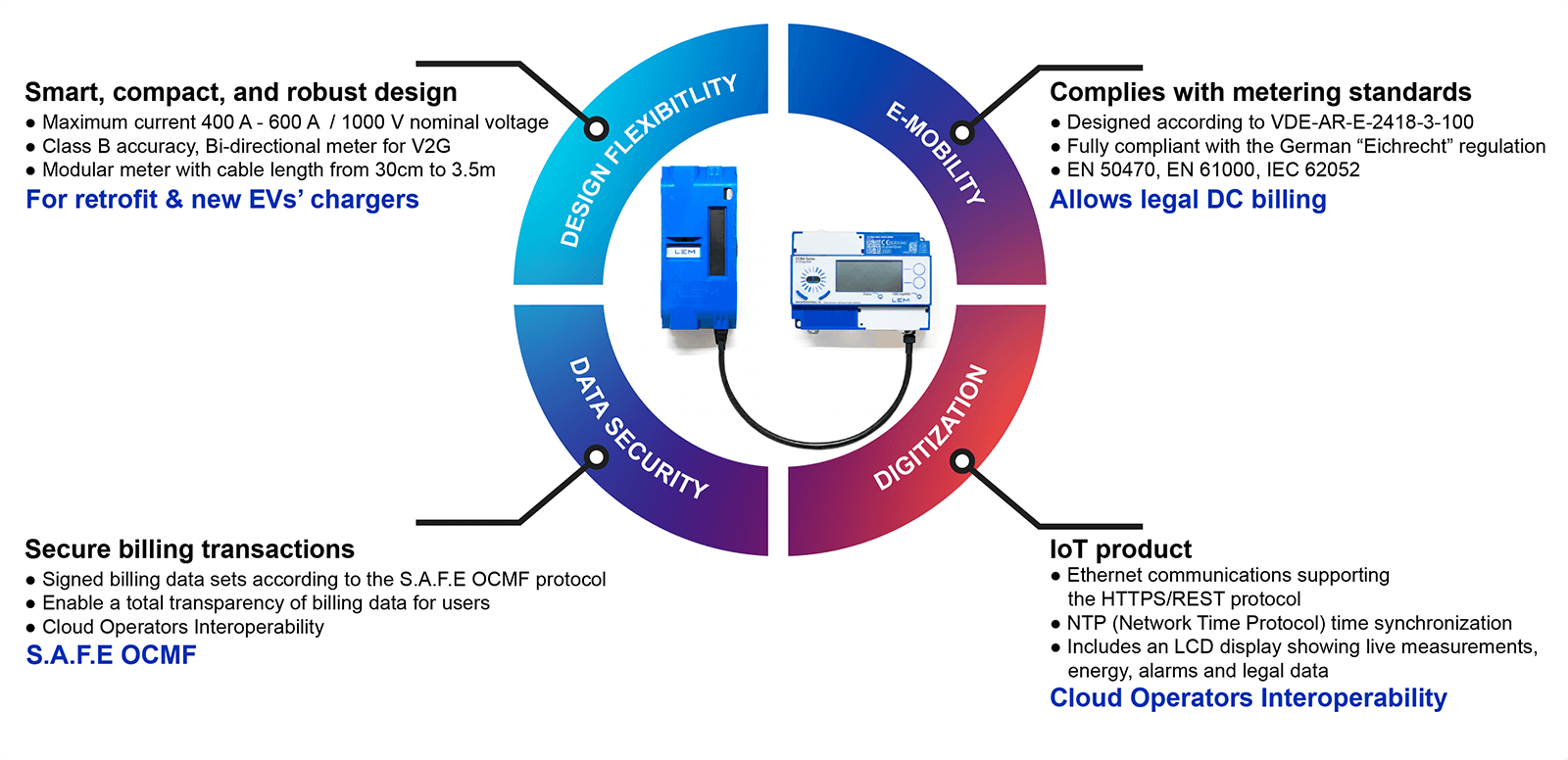

The new DC Billing Meter (DCBM) from LEM is a smart and compact billing solution that will help electric vehicle charging stations take advantage of the benefits of DC charging.

Offering a power measurement range from 25kW to 600kW, the DCBM is a legal and certified meter that provides accurate billing of DC chargers.

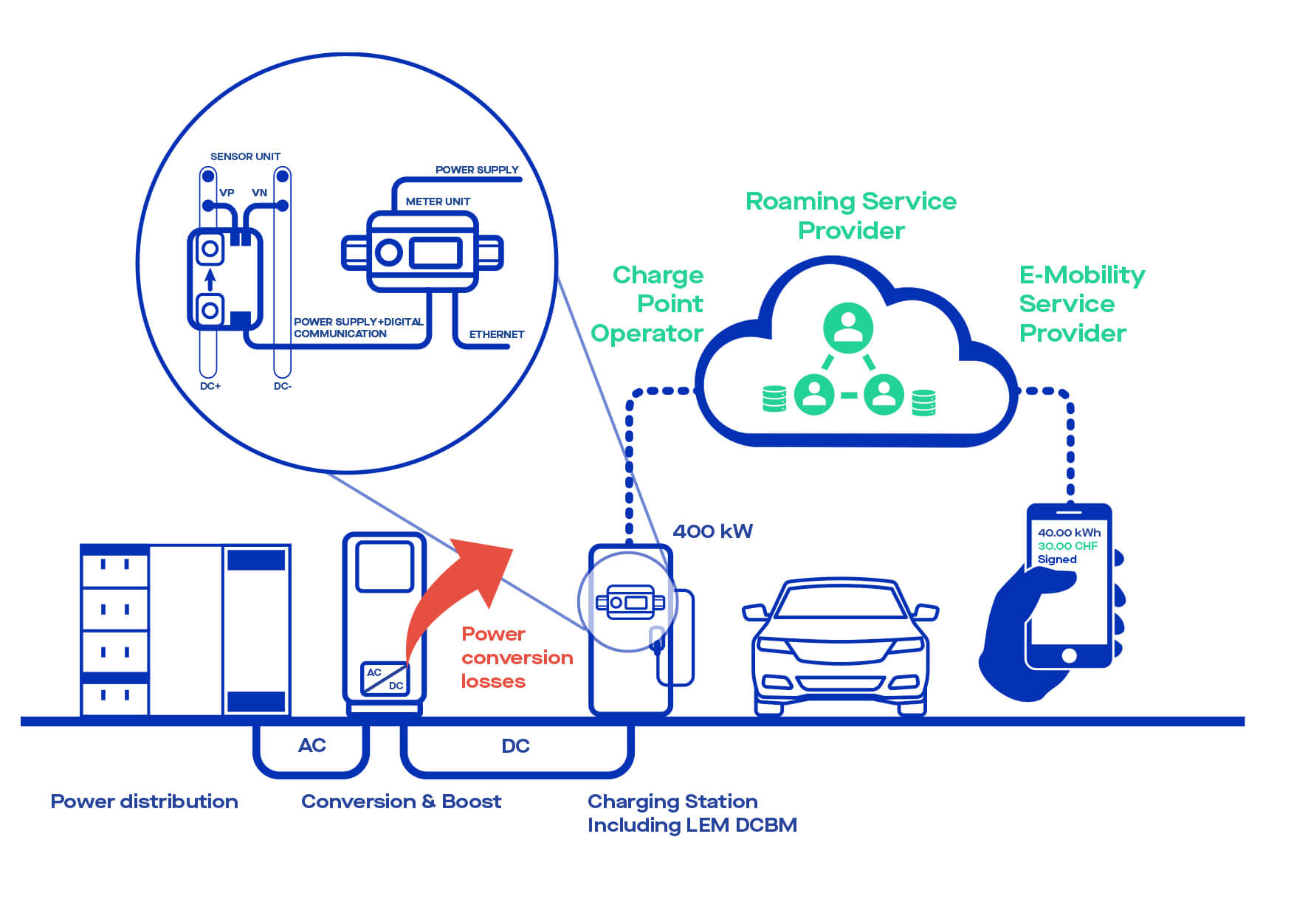

To reduce this charging time to only a few minutes, charger manufacturers convert the AC into a direct current (DC) outside the car, bypassing the On-Board-Charger (OBC) and supplying the battery pack of the electric vehicle directly. This method can boost charging power up to 400 kilowatts. However, this conversion stage generates power losses, which do not have to be paid for by the end user, the EV’s owner. Thus, an electric meter is placed after the conversion stage to monitor and bill the exact energy transferred to the electric vehicle.

DC Meter smart billing

Need help with a project?

You have a project in line with that application and want to discuss it with LEM?

Click on the contact button below and our experts will help you find the best solutions for your needs.