Current measurement in industrial welding applications

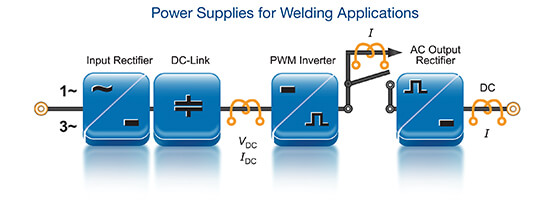

For a welding process to be successful, the 2 parts to be welded must be exposed to an intense heating source usually created with an electrical arc which temperature can reach up to 3000°C. The quality of the welding depends, among others, on a high control of this electrical arc and of the electrical current used to produce it. LEM transducers measure this current, contributing to the control and good function of the welding application.

MAIN APPLICATIONS FOR WELDING new

Typical applications for Welding

- Power supplies for welding

- Power supplies for plasma welding

- Plasma cutting

- Electrolysis

- Inductive heating

Plasma arc welding: control and accuracy

The plasma arc welding process was introduced to better control the arc welding process in lower current ranges. Plasma enables an advanced level of control and accuracy in order to:

- produce high quality welds in miniature or high-precision applications

- increases electrodes’ life for high-production requirements

Plasma arc welding requires high current levels anywhere between 100 and 600 ampere. Depending on the type of material used and object welded, a specific current profile must also be maintained to ensure a high-quality weld. This is the role of LEM’s transducers. They measure and control precisely the level of current that is used to heat the plasma, ensuring a strong and lasting weld.

Products for Welding

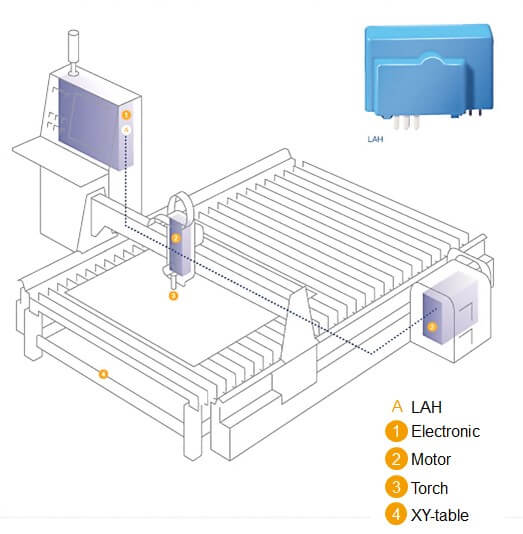

Application example

Certificates and standards

Compliance with the highest industry standards

LEM products and processes comply with reference standards in the industry:

- CE marking of LEM transducers in recognition of their electromagnetic compatibility

- IEC standards for welding applications:

- IEC 61800-5-1 for safety

- IEC 61800-1 & IEC 61800-2 for climatic and mechanical constraints

- IEC 61800-3 for EMC

- RoHS compliant

- ISO TS 16949 certification of all production and development centers (Switzerland and China)

- IRIS certification :

- Geneva Head Office since September 2007 (LEM Switzerland SA)

- Beijing production sites since 2008 (LEM Electronics China Co. Ltd)

- Sofia production site since 2016 (LEM Bulgaria EOOD)

Quality products and services: our priority

Based on our deep knowledge of applications and current measurement technologies, LEM develops both catalog and customized products which can be perfectly tailored to meet your needs in terms of performance, space requirement and cost.

Related information

Need help with a project?

You have a project in line with that application and want to discuss it with LEM?

Click on the contact button below and our experts will help you find the best solutions for your needs.