Air-core Current Sensors

The performance of current sensors and voltage sensors are often limited by the characteristics of the magnetic core material itself (e.g. remanence, hysteresis, non-linearity, losses, saturation) so the design of an air-core, or coreless, sensor is often considered.

Air-core technologies principles

When considering an air-core current sensor design, several issues need to be taken into account.

The measurement of DC current requires the use of a field sensing element; due to the absence of a field focused area, a highly sensitive field sensing device must be considered ideally in an array around the conductor.

When available, a magnetic circuit can be used as a shield to external magnetic field disturbances; with air-core technologies the sensitivity to external disturbances must be managed in a different way, for example an array of field sensors instead of a single sensor or, when coils are considered, special design execution such as the Rogowski method of routing the return wire; the ability to accurately measure the desired current while also rejecting external fields is a significant challenge for air-core technologies.

Three efficient air-core sensors technologies are introduced below: the Rogowski, PRiME™ and Split core current transformer technologies.

Rogowski Current Sensors RT type

Features

- Non-contact measurement of AC & pulsed signal

- Thin, lightweight & flexible measuring head

- Easy to use: can be opened

- Sensitivity to external field disturbances minimized

- Wide frequency range

- Galvanic isolation

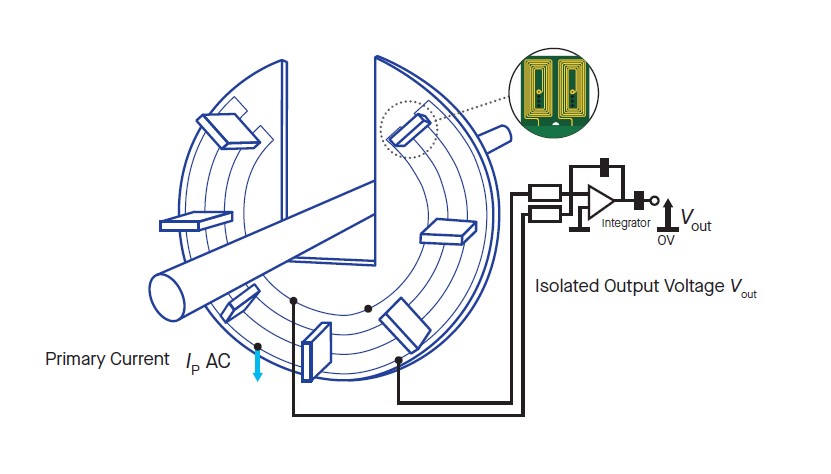

Operation principle Rogowski Current Sensors RT type

Rogowski technology is an Air-core technology (without magnetic circuit).

A pick-up coil is magnetically coupled with the flux created by the current to be measured IP. A voltage VOUT is induced on the pick-up coil proportional to the derivative of flux and thus proportional to the derivative of the current to be measured IP. Because the derivative of DC is zero this technology is only useful for the measurement of AC or pulsed currents.

The waveform of the measured current requires the integration of the induced voltage VOUT. Therefore, the current transducer may includes an integration function in the processing electronics (option).

Typical applications of Rogowski RT type current transducers

Rogowski RT type current sensors has a lightweight measuring head combined with remote electronics (distance between head and electronics can be as great as 4 meters, or 12 feet).

This, along with all of the previous described attributes, lead to a device suitable for use in a wide range of applications.

- Smart Grid

- Measuring currents in busbar sets, in particular in induction heating equipment.

- Frequency converters, variable speed drives and generators.

- Control of power semiconductors.

- Analysis of the current distribution in mains networks.

- Analysis of harmonics, power measurements, measurement of the peak load in the mains, and in UPS.

- Switched mode power supplies.

- Low or medium voltage distribution installations.

- Power electronics installations.

- Sensing devices for watt meters and network analyzers installed by electric power distribution companies.

- Electrical maintenance, repair and machine installation and start-up applications.

- Connection to most measuring instruments including multimeters, oscilloscopes, recording devices, data loggers, etc.

PRiME Current Sensors

Features

- AC measurement with wide dynamic range

- No magnetic saturation

- High overload capacity

- Good linearity

- Accuracy independent of the position of the cable in the aperture and of external fields

- Light weight and small package

- Low thermal losses

Operation principle PRiME Current Sensors

PRiME operates on the basic Rogowski principle.

Instead of a traditional wound coil, the measuring head is made of a number of sensor printed circuit boards (PCBs, each made of two separate air cored coils) mounted on a base-PCB.

Each sensor PCB is connected in series to form two concentric loops. The induced voltage at their outputs is then integrated in order to obtain both amplitude and phase information for the current being measured.

Typical applications of PRiME current transducers

PRiME current sensors are mainly used in the renewable energies and the automation domains. That technology can also be used in the following applications:

Typical applications include:

- Automation systems: Analog current reading for remote monitoring (e.g. motor) and sotware alarms.

- Panel meters: Simple connection to power consumption displays.

- VFD Controlled Loads: VFD output indicates how the motor and attached load are operating.

- SCR Controlled Loads: Accurate measurement of phase angle fired or burst fired (time proportioned) SCRs. Current measurement gives faster response than temperature measurement.

- Switching Power Supplies and Electronic Ballasts: True rms sensing is the most accurate way to measure power supply or ballast input power

Split Core Current transformers AT & TT type

Features

- Non-contact measurement

- AC & pulsed signal

- No power supply

- Easy to use: Can be opened

- Good overall accuracy

- Galvanic isolation

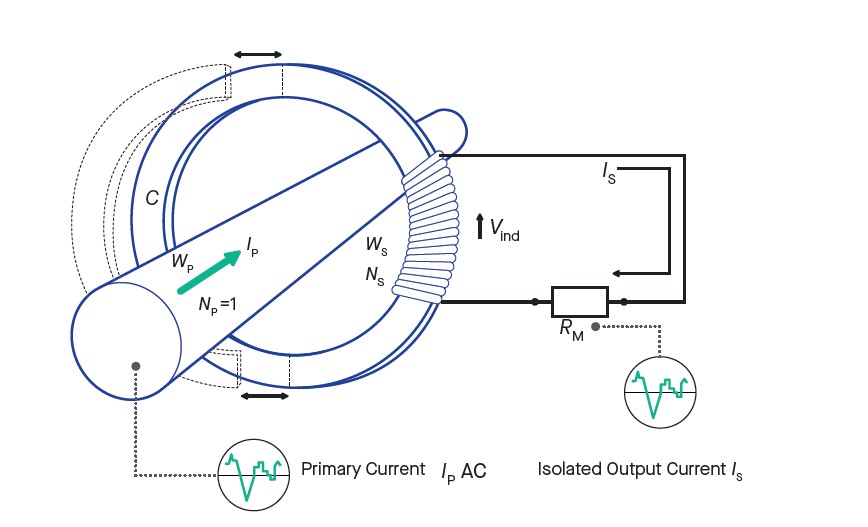

Operation principle Split Core Current transformers AT & TT type

A transformer is a static electrical device transferring energy by inductive coupling between the windings making part of it. It is made with a primary coil (WP) with NP turns and a secondary coil (WS) with NS turns, wound around the same magnetic core (C).

A varying current IP in the primary winding (assimilated here to the primary conductor crossing the aperture: NP = 1) creates a varying magnetic flux in the transformer’s core crossing the secondary winding. This varying magnetic flux induces a varying electromotive force or voltage Vind in the secondary winding. Connecting a load to the secondary winding causes a current IS to flow. This compensating secondary current IS is substantially proportional to the primary current IP to be measured so that NP.IP = NS.IS

DC currents are not measured and not suitable because they represent a risk of magnetic saturation. The relationship here above is respected only within the bandwidth of the current transformer.

Warning!: Never let the output unloaded because there is a risk of safety for users.

Typical applications of Split Core Current Transformers AT & TT Type

Split Core AT & TT Type current transformers are used in Smart Grid and Automation environments.

Typical applications include:

- Automation and Supervision: Current measurement for process regulation by distributed PLCs or remote control (e.g. SCADA software)

- Safety and Condition Monitoring: Load monitoring for protection systems and predictive maintenance (e.g. conveyers, pumps or HVAC motors)

- Energy management: Convenient connection to power consumption sub-meters

- Power meter: Current measurement for active power calculation

- Energy sub-meters: For energy efficiency monitoring, consumption analysis and costs allocation

- Power quality monitoring

- Conditions monitoring (e.g. moto leads such as conveyers, pumps or HVAC)

- Distributed measurement systems