Battery Management System

LEM works with all the major car manufacturers and Tier-1 suppliers in the world and supplies galvanically isolated current sensors that meet high standards of functional safety (ASIL) in battery-management and automotive motor-control applications.

LEM provides its customers with an extensive range of products designed for High Voltage (HV) BMS as well as for 12V battery management systems (ICE and start-stop vehicles).

Why are automotive sensors so important in BMS applications?

The ambitious goals for achieving net zero emissions are prompting OEMs to accelerate the development of xEVs and reduce their Time-to-Market strategy, as transportation is a crucial component of this initiative. The widespread adoption of electric vehicles by a significant portion of the population presents a challenge for OEMs and compels engineers to address the pressing issue of range anxiety associated with the use of Li-Ion batteries.

Through intricate algorithms, engineers have identified two critical parameters: SOC (State-of-Charge) and SOH (State-of-Health), which are calculated by the BMS (Battery Management System), the controlling device of the battery pack.

The SOC, familiar to the driver as it's displayed on the dashboard as a gauge icon, is determined by the ratio of the available capacity to the maximum possible charge that a battery can hold. The current flowing into and out of the battery is the most crucial information for obtaining the most accurate SOC.

As such, automotive current sensors plays a vital role in estimating and extending the battery's autonomy, gradually building customer trust in xEVs and advancing electrification.

Moreover, having a high voltage system embedded in the car imposes on OEMs to adopt a high safety level to ensure the protection of the driver against a risk of fire in the battery pack. An overcurrent event not detected can lead to such issue.

This is where the current sensor plays a second key role by detecting the overcurrent and inform the BMS so it can quickly react by opening the contactors or trigger a pyrofuse.

SMART AUTOMOTIVE BATTERY MANAGEMENT TO REDUCE OVERALL ENERGY CONSUMPTION

LEM is specialized in developing and manufacturing current sensors for battery management sytems (BMS) and motor drive applications in cars, buses and trucks. By controlling the current in energy-intensive applications, LEM participates in the global effort to reduce overall energy consumption.

In high voltage battery management (BMS HV), the CAB series integrates LEM's expertise in fluxgate technology, offering best-in-class accuracy and a high level of functional safety (ASIL). This eliminates the need for a redundant sensor installation.

For start-stop vehicle architectures, LEM provide intelligent automotive battery sensors that leverage our unique proficiency in current sensing, coupled with over two decades of experience in lead acid battery technologies.

Our product lineup encompasses a diverse range of single-phase Hall open-loop sensors known for their high compactness, featuring an integrated busbar for cost-effectiveness.

LEM has also engineered dual-range sensors, incorporating a dedicated low range to significantly enhance offset performance while maintaining exceptional accuracy.

Typical applications for automotive sensors include:

- Standard battery monitoring

- Hybrid and EV battery pack current sensing

- Fuel cell current control

- DC/DC converters and AC/DC inverters

- Hybrid and EV motor inverter drive

- EPS and X-by-wire applications

- Electric compressors for air conditioning

What functions does a Battery Management System primarily serve?

Battery Protection

- Preventing operations outside the safe operating area to ensure the safety and integrity of the battery pack.

- Monitoring and controlling parameters such as temperature, voltage, and current to avoid overcharging, over-discharging, and overheating.

Battery Monitoring

- Estimating the battery pack's State of Charge (SoC) and State of Health (SoH) during charging and discharging.

- Providing real-time information on the battery's performance and overall condition.

Battery Optimization

- Implementing cell balancing to equalize the charge among individual cells within the battery pack.

- Improving battery life and capacity, optimizing the driving range for various types of electric vehicles, including Hybrid Electric Vehicles (HEV), Plug-In Hybrid Electric Vehicles (PHEV), and Battery Electric Vehicles (BEV).

- These functions collectively contribute to the safe and efficient operation of electric vehicle batteries, ensuring longevity, performance, and reliability.

High Voltage Battery Management Systems (HV BMS)

Battery management for hybrid and electric vehicles (EV) markets

The production of electric cars and hybrid vehicles is increasing.

Both types of vehicles need high current capability batteries to run the 50kW or more motors and these use high voltage systems.

Shunt, Fluxgate and Hall-effect are the technologies of choice for this application. While the shunt is the preferred technology because of their simplicity of use and excellent linearity, fluxgate brings a better accuracy especially on the offset. On the other hand, open loop hall effect sensors bring the advantage of a cost-effective solution for redundant functions.

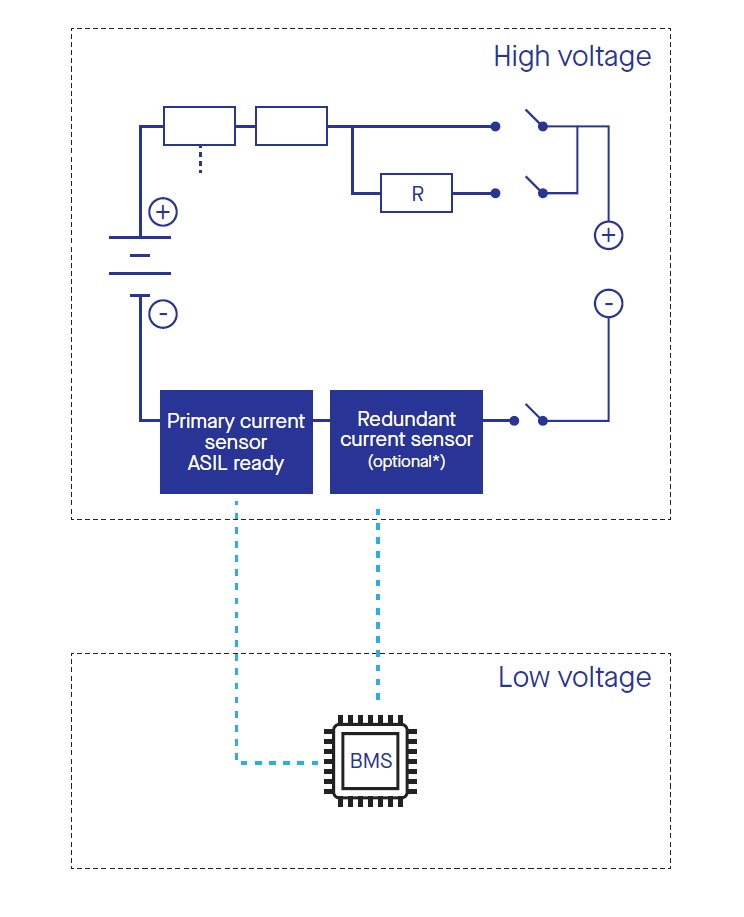

Battery Disconnecting Unit Architecture in Hybrid & Electric Vehicles

Shunt automotive battery sensors

Shunt BMS sensors, which operate on the principle of Ohm's Law where the voltage drop across the shunt is directly proportional to the current flowing through it, are capable of measuring both alternating currents (AC) and direct currents (DC).

These low-resistance, cost-effective shunt sensors are a preferred option for automotive battery management system current measurement due to their high reliability.

The shunt technology provides a mechanical and electrical design that is apt for applications involving both light and heavy-duty tasks with multiple batteries.

Fluxgate BMS sensors for hybrid and EVs

LEM possesses a distinctive expertise in fluxgate technology, recognized as a leading solution for high-performance battery management, providing contactless solutions.

Here are key features of LEM’s CAB series within this technology:

CAB Series

- Best-in-class accuracy, achieving up to 0.5% over full T°C range after endurance tests.

- Offset at 50mA measurement for precise current sensing.

- ASIL readiness, eliminating the need for a redundant sensor: ASIL B (CAB-SF 500), ASIL C (CAB-SF 1500).

- Integration within the battery disconnection unit (BDU) or the battery pack of vehicles equipped with electrified powertrains (xEV ). Compatible with 800V systems.

This demonstrates LEM's commitment to advanced technology, ensuring accurate and reliable battery management in electrified vehicles.

Hall open loop Battery Management Sensors for hybrid and electric vehicles

LEM's wide range of single-range sensors is characterized by:

- High Compactness: The sensors are designed with a compact form factor.

- Integrated Busbar Design: Cost-effective integration with an integrated busbar.

Additionally, LEM has developed a high-precision dual-range sensor that includes a dedicated low range. This innovative design significantly enhances offset performance, ensuring accurate current measurement.

LEM's Hall-based products are well-suited for electronic current measurement in applications with high power and low voltage. The key features of these products include:

- Galvanic Separation: Ensures isolation between the primary circuit (high power) and the secondary circuit (electronic circuit).

- Range Flexibility: LEM offers a range of current measurement options within the same housing, allowing users to choose based on their specific requirements.

- Excellent Accuracy and Linearity: The sensors provide high accuracy and excellent linearity, contributing to reliable and precise current measurements.

- Low Thermal Offset and Sensitivity Drifts: LEM's sensors are designed to minimize thermal offset and sensitivity drifts, maintaining accuracy even in varying temperature conditions.

Here are key features of LEM’s SMU series within this technology:

SMU Series

- Accurate State of Charge (SOC) Estimation: The SMU provides precise SOC estimation, which is crucial for efficient battery management in EVs.

- High Insulation Levels: It ensures high insulation between the primary (high power) and secondary (electronic) circuits, enhancing safety.

- Temperature Resilience: It operates effectively within a broad temperature range of -40°C to +125°C, ensuring reliability in different environmental condition.

- ASIL B Readiness: The SMU is designed to meet Automotive Safety Integrity Level B (ASIL B) requirements, ensuring high safety standards for automotive applications.

HIGH VOLTAGE BATTERY MANAGEMENT SYSTEM PRODUCTS (HV BMS)

| Sensor Family | ||||||

|---|---|---|---|---|---|---|

| Technology | Open loop | Open loop | Open loop dual range | Open loop dual range | Open loop | Fluxgate |

| Current range max | +/- 1000 A | +/- 1200A | +/- x00A +/-1000A | +/- x00A +/-1000A | +/-1500A | +/- 500A +/-1500A |

| ASIL readiness | - | - | - | - | ASIL B | ASIL B, ASIL C |

| Output | Voltage single | Voltage single/dual | Voltage single/dual | Voltage dual | LIN | CAN |

| Global error @25°C | 1,2% | 1,2% | 1,2% | 1,2% | 1,0% | 0,1% |

| Overall accuracy (over T°C) | 2,25% | 2,25% | 2,25% | 2,25% | 1% at 1350A 1.33% at 1500A | 0,5% |

| Bandwidth (programmable) | 1,1 kHz | 1,1 kHz | 1,1 kHz | 1,1 kHz | 20 Hz | 100 Hz |

| Mounting type | Busbar | Busbar | Integrated busbar | Cable/Busbar | Integrated Busbar | Cable/Busbar |

| Input voltage | +5V | +5V | +5V | +5V | +12V | +12V |

| Consumption | 7 mA | 8/16 mA | Single 7 mA Dual 14 mA | 16 mA | 15mA | 40 mA (OA) 130 mA – 500 mA (@500A – 1500A) |

12V Battery Management Systems

LEM possesses substantial expertise in the development of galvanically-isolated current sensors tailored for 12V battery management. These sensors serve both standard internal combustion engines (ICE) and intelligent Battery Management Systems (BMS) designed for start-stop powertrains.

- ICE Vehicles: With over two decades of experience in 12V Battery Management Systems (BMS) for lead-acid batteries, LEM offers a comprehensive product portfolio designed for standard ICE powertrains.

- Start-Stop Vehicles: LEM offers a variety of intelligent battery current sensors specifically designed for start-stop vehicles. These sensors leverage LEM's unique expertise in current sensing technologies, coupled with extensive experience in lead-acid battery technologies gained over the years.

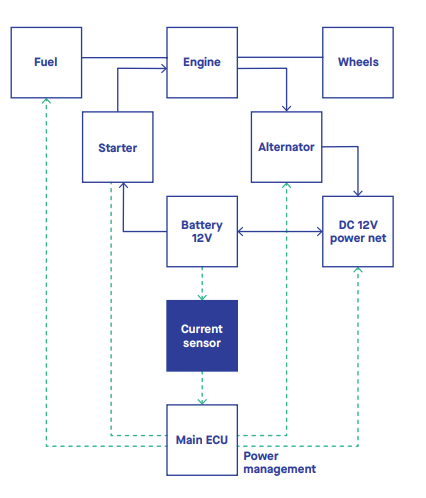

12V battery current sensor in vehicles

Conventional battery management

Car makers have been focusing their attention on reducing fuel consumption for several years. Currently, the main focus is to reduce fuel usage by managing the charging of the main battery. Early progress in energy management has now shifted focus and is heavily concerned with power management. This includes managing the battery, the combination of additional functions of the battery’s state of health and safety features, such as auto-disconnect.

Secondary functions have been reduced and the size of the alternator has been optimized thus instantly reducing global electrical consumption.

In the example of a start-stop vehicle, the current sensors allow the battery management system (BMS) to decide if enough energy is available in the battery to operate the accessories (such as aid-conditioning, headlights, and radio) while the engine is off, and still have ample charge left to restart the engine.

The "engine control unit" will instruct the "starter generator" to restart the engine or recharge the battery, as needed, and current sensors used at the output of the rectifier modules allow it to operate smoothly, improving the driver experience while helping the environment.

Generator current monitoring

The need for higher energy in cars is increasing. Generators are required to provide more current to the vehicle loads and batteries, yet to be more efficient, the current needs to be controlled.

The HAB current sensor family is best suited to provide the BMS (Battery Management System) with the proper current information. Depending on the size of the car, this current can flow from 60A (conventional car) up to 240A (service cars and trucks).

Quality

LEM products meet all quality requirements for the automotive industry and comply with RoHS specifications. All our production and development centers are certified with ISO TS 16949 (in Switzerland and in China). Based on our deep knowledge of applications and current measurement technologies, LEM develops both catalog and customized products which can be perfectly tailored to meet your needs in terms of performance, space requirement and cost.

PRODUCT DOCUMENTATION

Discover LEM’s leading technologies for automotive applications. Our automotive expertise does not only cover Battery Management Systems. LEM also provides innovative solutions for motor control and electric vehicles supply equipment (EVSE). Dive into the details and download our brochure for an insightful exploration:

Need help with a project?

You have a project in line with that application and want to discuss it with LEM?

Click on the contact button below and our experts will help you find the best solutions for your needs.