HC16F Family

A highly flexible design to measure DC link current as well as phase current in motor control applications

HC16F - Automotive Motor Control current sensors

The HC16F family of sensors is specifically designed for the electronic measurement of DC, AC, or pulsed currents in high-power automotive applications, spanning both high and low voltage systems, while ensuring galvanic isolation between the primary circuit (high power) and the secondary circuit (electronic circuit).

One notable feature of the HC16F family is its ability to offer various current measuring ranges within a single housing, providing flexibility to meet different application requirements.

These automotive current sensors operate based on open-loop Hall effect technology. The precise assembly and calibration of a LEM-designed magnetic core combined with a LEM proprietary ASIC (Application-Specific Integrated Circuit) result in exceptional performance, making them well-suited for demanding automotive applications.

HC16F – Features and benefits

Features

- Ratiometric transducer

- Open Loop transducer using the Hall Effect

- High and Low voltage application

- Unipolar +5 V DC power supply

- Primary current measuring range ±1000 A to ±1600 A

- Maximum RMS primary admissible current: defined by busbar to have T < +150 °C

- Operating temperature range: −40 °C < T < +125 °C

- Output voltage: full ratio-metric (in sensitivity and offset)

- Compact design for PCB mounting

Main characteristics

- Excellent accuracy

- Very good linearity

- Very low thermal offset drift

- Very low thermal sensitivity drift

- Galvanic separation

- High frequency bandwidth

Typical applications

The HC16F family of sensors is meticulously designed for automotive applications, showcasing versatility in a range of scenarios within this domain, including:

- Electrical Power Steering

- Starter Generators

- Converters

- Motor drive application

HC16F FOR UP TO 1,600 A

The HC16F is the latest development from LEM to meet the need for high current and high accuracy sensing in a small, light, and easy to mount package. While the overall footprint is defined by the busbar opening, the LEM design with dual airgap allows significant reduction of the size and weight of the magnetic core, improving vibration characteristics as well as reducing usage and cost of raw materials compared to a traditional C-core sensor. HC16F is only 37.2x32.6 mm for 29g while it can measure up to 1600 A!

In addition, the HC16F family provides excellent immunity against cross talk thanks to a dual ASIC configuration that cancels the effect from external fields.

HC16F SERIES, A HIGH FLEXIBLE DESIGN

In the typical structure of inverters, which often include a vertical arrangement of a cooling jacket, power module, and gate driver board, the HC16F automotive sensors can be conveniently mounted flat directly onto the gate driver board. This placement allows them to sense the current passing through the busbar via the PCB, connecting the power module to the motor connector.

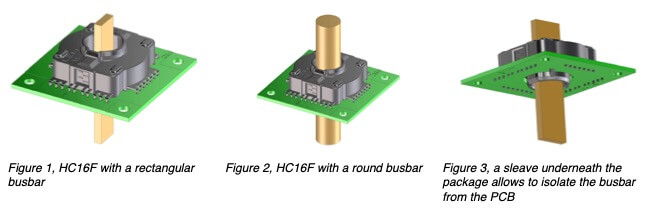

The round aperture of these sensors is designed to accommodate both rectangular and round busbars, offering flexibility in busbar design. Additionally, the inclusion of a sleeve beneath the package, passing through the PCB, serves to isolate the busbar and meet high voltage isolation requirements.

HC16F sensors are available in through-hole or pin-in-paste, eliminating the need for an external connector and simplifying the sensor assembly process, which can lead to cost savings.

LEM HC16F – Download & Technical Characteristic

| Product | Order | Document | Primary nominal RMS voltage | Package size | PCB connection | Insulation voltage | Creepage |

|---|---|---|---|---|---|---|---|

| HC16F 1000-S00 | Datasheet 3D | 1000 A | 37.5 x 37.5 x 12.7 mm | Plated Through Hole (THD) Pin in Paste compatible | 3.6 kV | 11 mm, PLC3 | |

| HC16F 1100-S00 |

| Datasheet | 1100 A | 37.5 x 37.5 x 12.7 mm | Plated Through Hole (THD) Pin in Paste compatible | 3.6 kV | 11 mm, PLC3 |

| HC16F 1200-S00 |

| Datasheet | 1200 A | 37.5 x 37.5 x 12.7 mm | Plated Through Hole (THD) Pin in Paste compatible | 3.6 kV | 11 mm, PLC3 |

| HC16F 1300-S00 |

| Datasheet | 1300 A | 37.5 x 37.5 x 12.7 mm | Plated Through Hole (THD) Pin in Paste compatible | 3.6 kV | 11 mm, PLC3 |

| HC16F 1400-S00 | Datasheet | 1400 A | 37.5 x 37.5 x 12.7 mm | Plated Through Hole (THD) Pin in Paste compatible | 3.6 kV | 11 mm, PLC3 | |

| HC16F 1500-S00 |

| Datasheet | 1500 A | 37.5 x 37.5 x 12.7 mm | Plated Through Hole (THD) Pin in Paste compatible | 3.6 kV | 11 mm, PLC3 |

| HC16F 1600-S00 | Datasheet | 1600 A | 37.5 x 37.5 x 12.7 mm | Plated Through Hole (THD) Pin in Paste compatible | 3.6 kV | 11 mm, PLC3 |

HC16F Sensors - Ask for samples / quotation

Looking to receive samples or a quotation? Please click on the contact button below and provide us with the information you need on this product series. Our sales team will get back to you shortly.